SPRINGS

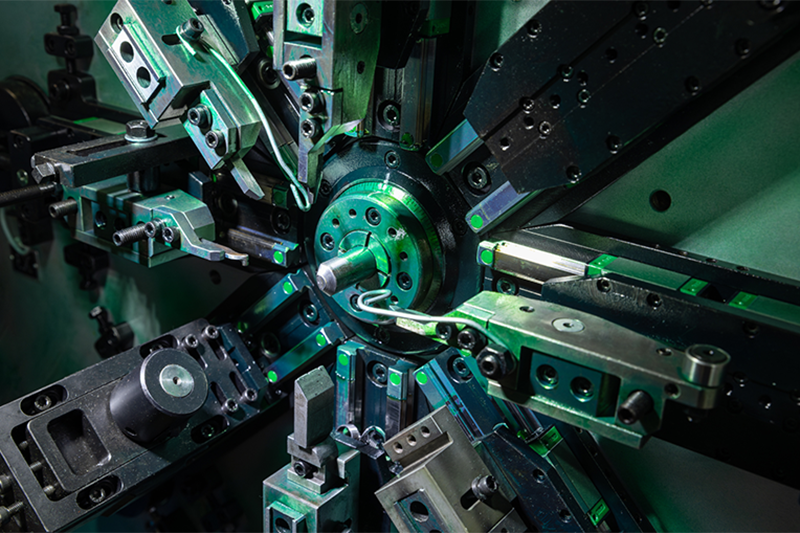

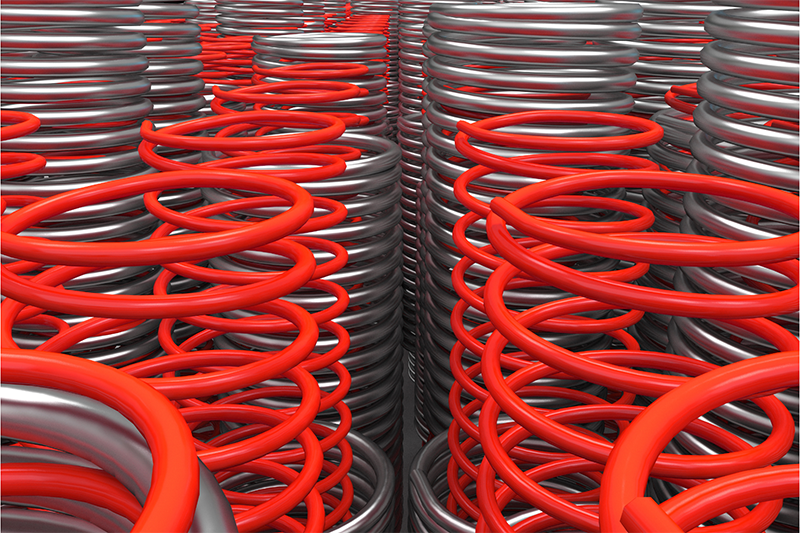

At our company, we take immense pride in our ability to produce high-quality industrial spring products tailored to meet our clients’ specific requirements. With a diverse range of materials and advanced manufacturing techniques, we can create springs that excel in durability, performance, and precision. Whether for automotive, aerospace, or any other industry, we understand that each application has unique demands. Our experienced team of engineers collaborates closely with clients to understand their needs and designs custom spring solutions that deliver optimal results. From compression springs to torsion springs, extension springs to wire forms, we have the expertise to manufacture products of exceptional quality and accuracy, ensuring they perform flawlessly under any conditions. With a steadfast commitment to excellence, we strive to delight our customers with our precise, reliable, and dependable industrial spring products made on request.

Springs 101

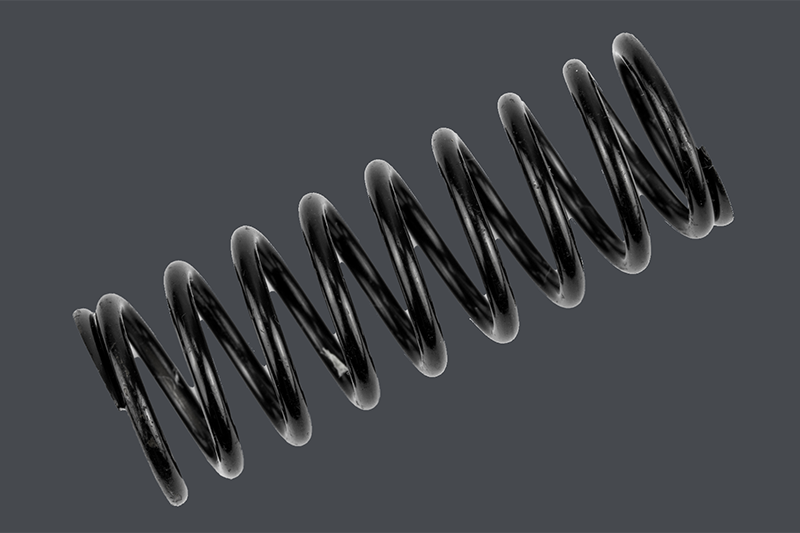

In the context of mechanics, a spring is a flexible component typically made of coiled or compressed material that stores mechanical energy when deformed and releases it when allowed to return to its original shape. It is used in a wide range of applications to exert force or provide suspension, allowing for the absorption of shock, the regulation of motion, or the storage of energy.

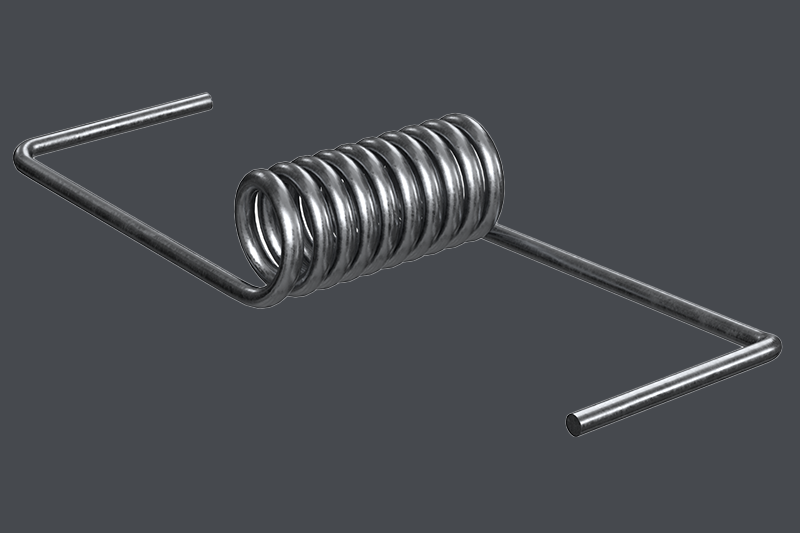

The behaviour of a spring is governed by Hooke’s Law, which states that the force exerted by a spring is directly proportional to the distance it is stretched or compressed. Springs come in various shapes and sizes, each designed to meet specific requirements based on the intended use, such as tension springs, compression springs, or torsion springs.

Whether you designed a new industrial suspension, or need to spring effect your next project, we have a solution for every sector.

Services:

- Linear springs;

- Variable rate springs;

- Constant force springs; and

- Coil springs.

Extra services:

- Flat springs;

- Disk springs;

- Machined springs; and

- Moulded springs.