MOULDING

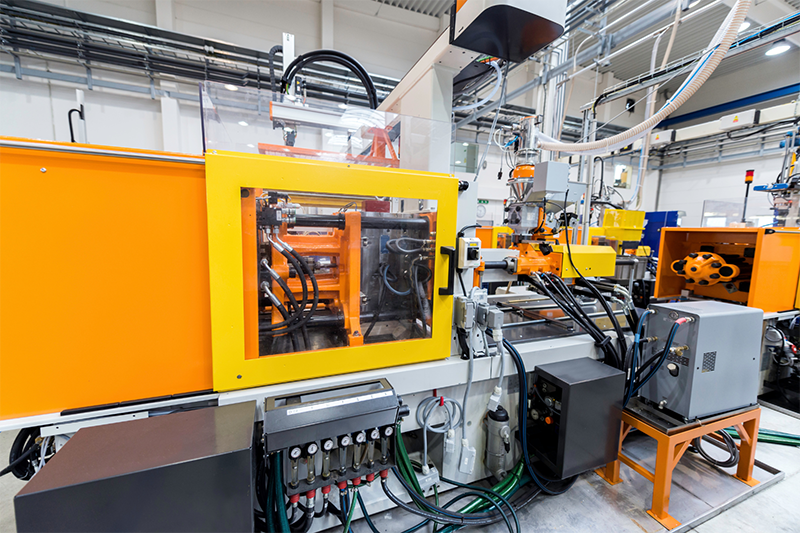

Our company is proud to offer top-notch plastic and metal moulding services. With our cutting-edge technology and skilled craftsmen, we excel in creating high-quality and precise moulded products. We specialize in both plastic and metal materials, catering to a wide range of industries and applications. Our state-of-the-art machinery ensures exceptional accuracy and consistency, resulting in flawless moulded components that meet the specific requirements of our clients. Whether it’s intricate plastic parts or robust metal components, our moulding services deliver exceptional durability and functionality. We prioritize customer satisfaction, providing reliable and efficient solutions that exceed expectations. Our extensive expertise and commitment to excellence make us the trusted choice for all your plastic and metal moulding needs.

Moulding 101

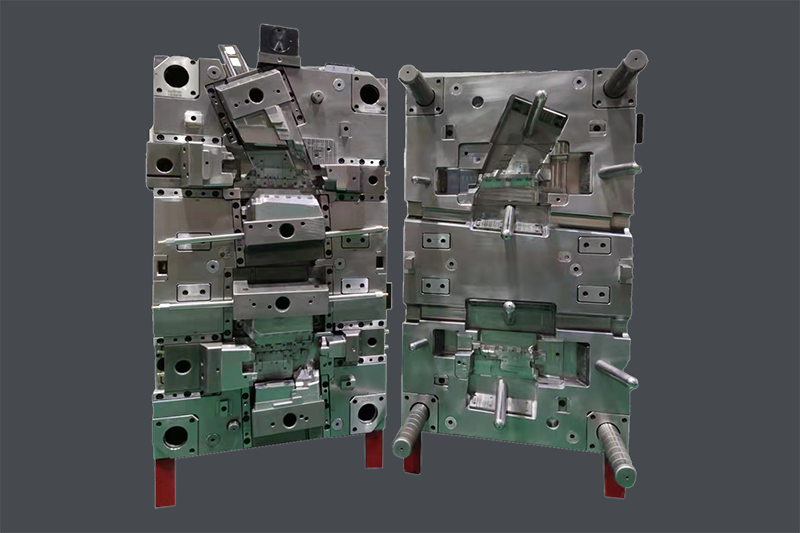

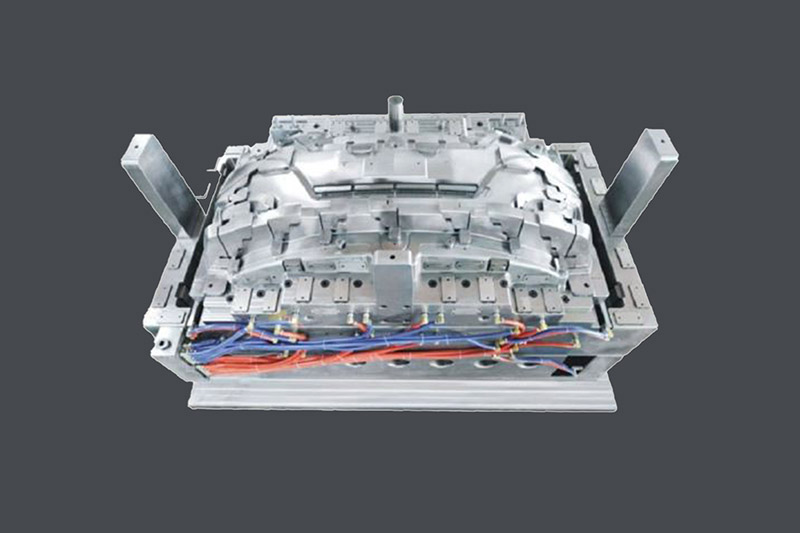

Plastic and metal components moulding is a fundamental process in manufacturing industries where raw materials are shaped into specific forms through moulds.

Plastic moulding involves heating plastic materials until they soften and injecting the molten material into a mould to cool and harden into the desired shape.

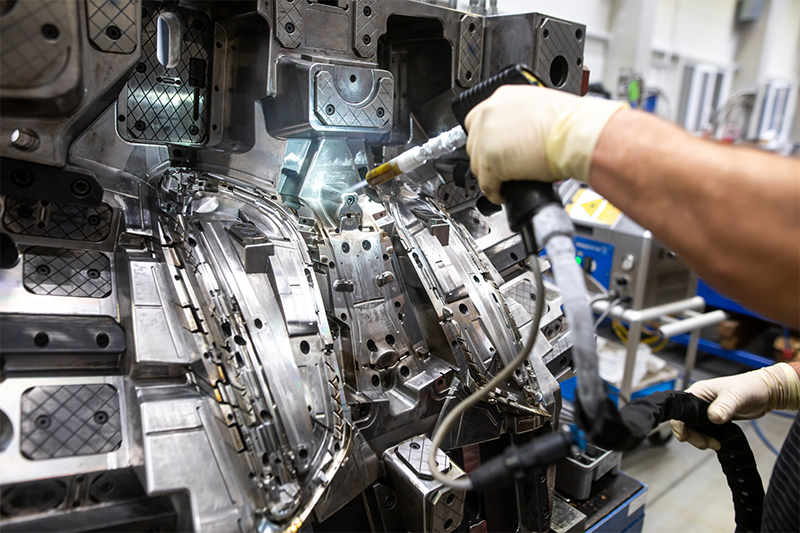

Metal moulding, on the other hand, typically requires high temperature to melt the metal, which is poured into a mould and cooled to solidify.

Both plastic and metal components moulding processes play a crucial role in producing a wide range of products found in various industries, from automotive to electronics, by creating parts with precise dimensions and properties. These moulded components are essential in achieving the structural integrity and functionality of the final products.

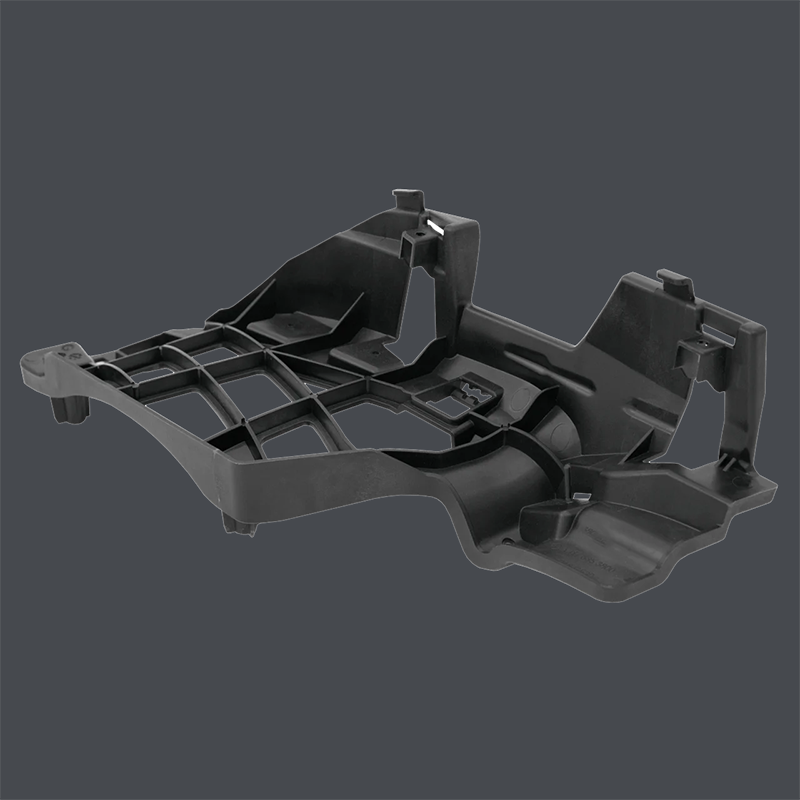

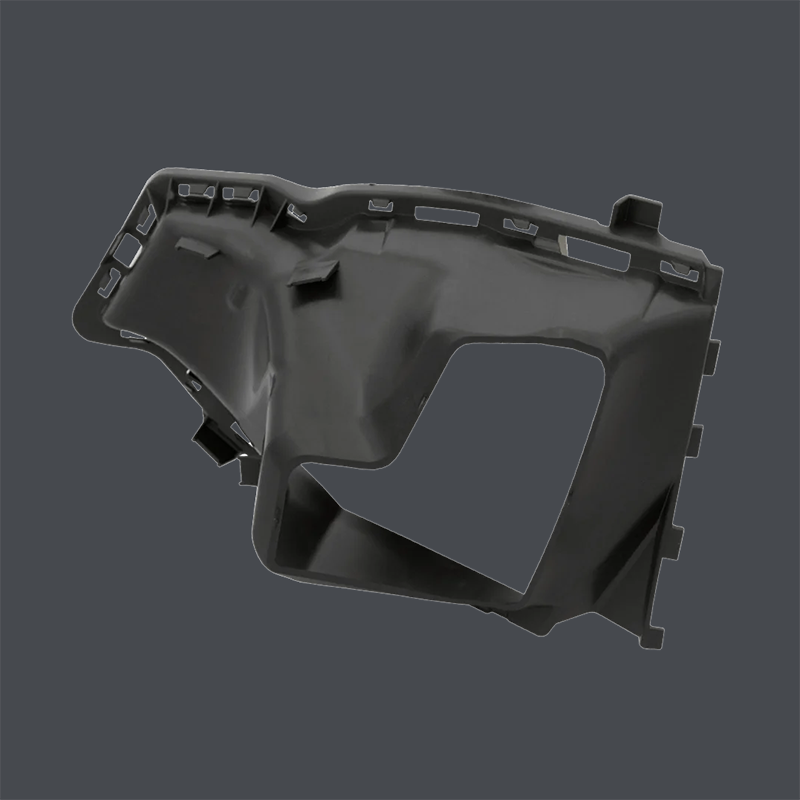

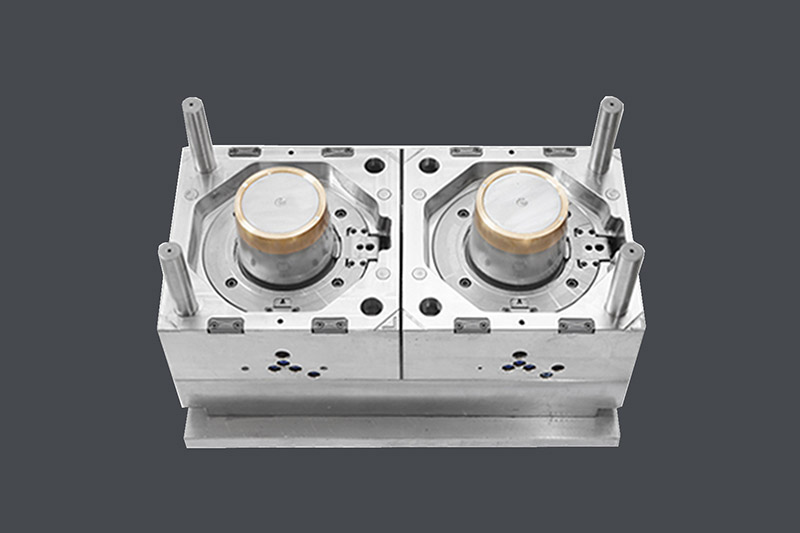

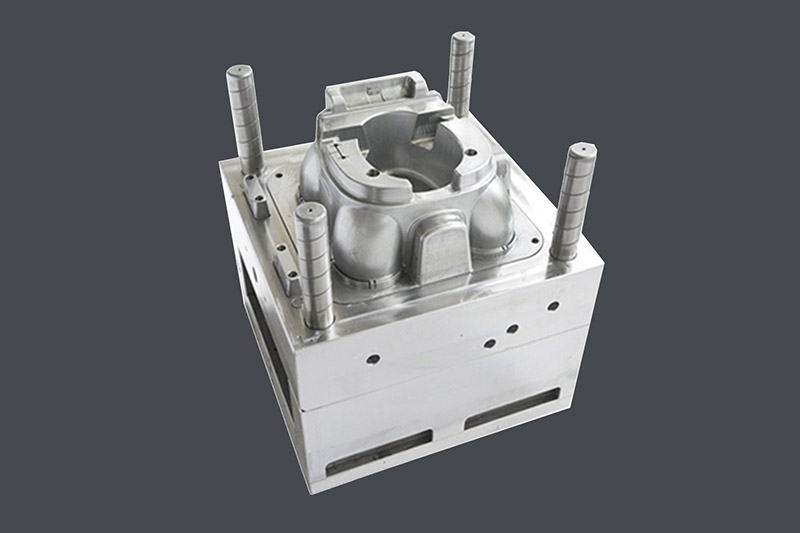

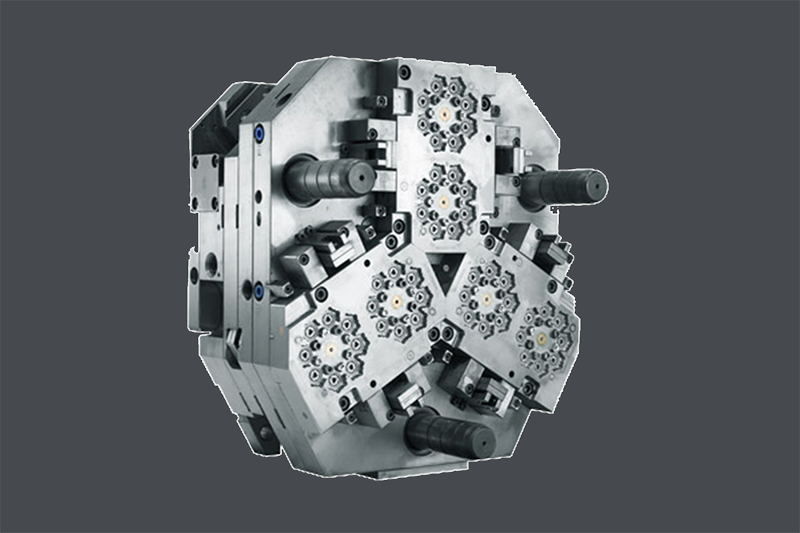

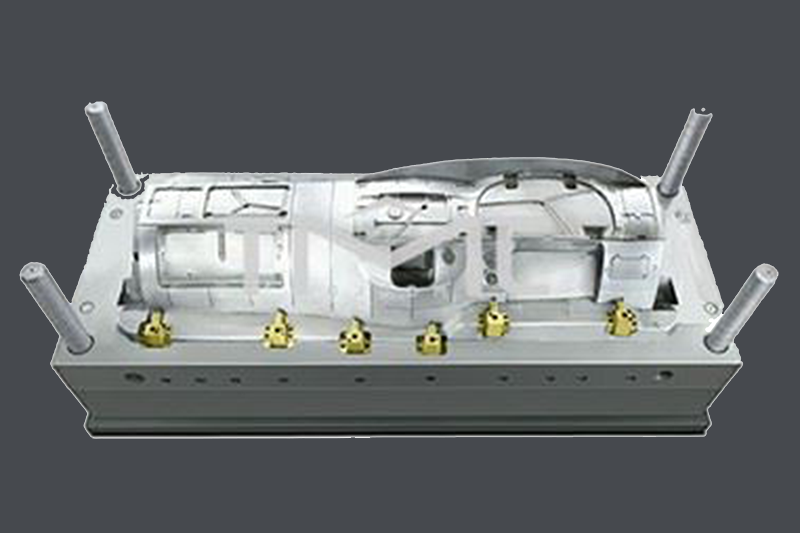

Some of our works

From automotive to home appliances, from transparent medical disposables to tools, we have a solution for every sector.

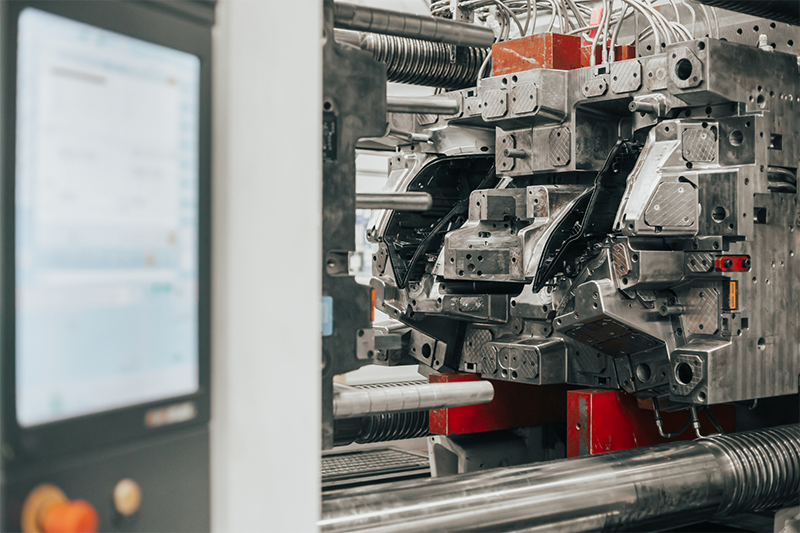

Services:

- Injection mould design and engineering;

- Design for Manufacturing (DFM);

- Precision plastic/ rubber injection mould;

- 2k precision plastic injection mould (plastic, rubber, metal inserts etc);

- Die-casting mould for aluminium; and

- Die-casting mould for Zamak.

Extra services:

- Moldflow Rheological Analysis;

- Co-engineering; and

- Special tool (customised).